In this article, our data acquisition SME, Diego Perdomo, talks about the value of Electronic Flow Measurement (EFM) data acquisition when implementing SMADA Solution.

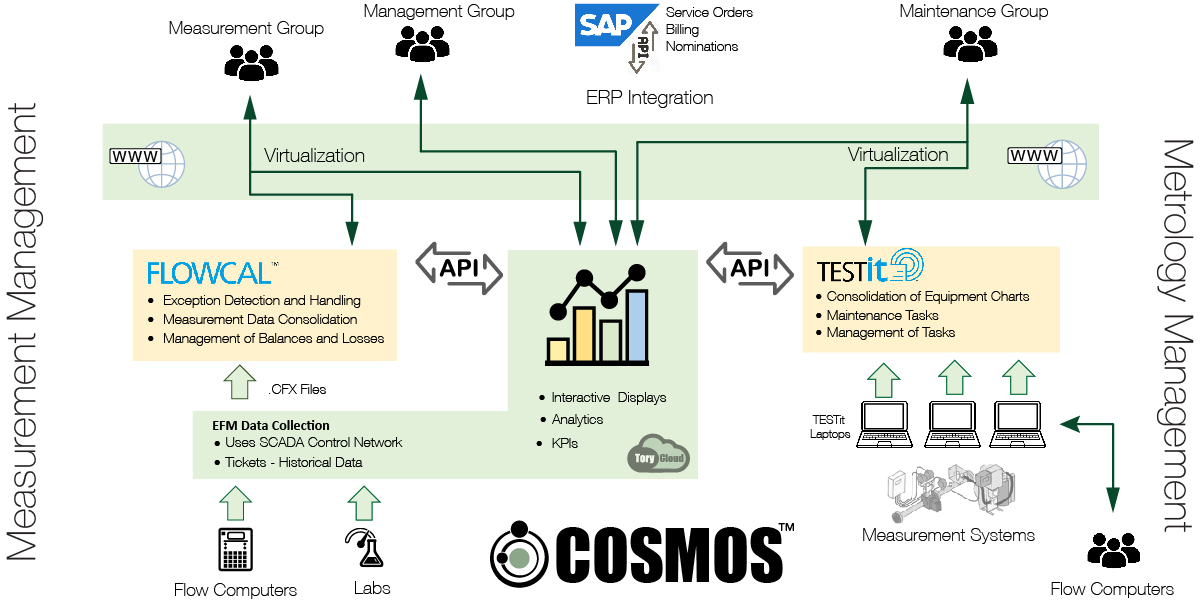

Under the SMADA concept, the field data acquisition level corresponds to one of the most important layers of the entire solution. This layer within the solution is known as ToryBridge. Its main objective is to collect measurement data from field devices and transfer it to the next level of the solution. The data is then evaluated and validated by FLOWCAL before being published to the corporate balance and billing systems.

The success of our SMADA system is based on considering each of the elements that make up the solution and ensuring its implementation is the most appropriate and efficient.

An example of the field data acquisition component was implemented for a truck loading terminal. The project’s scope included consolidating and validating all the measurement data recorded in the product delivery transactions to the trucks. This terminal had a considerable number of EMERSON DL-8000 flow computers. It was required to collect historical measurement data corresponding to the flow computers’ transactions (batches). One of the project’s challenges was to find a tool for the acquisition of historical data type EFM (Electronic Flow Measurement) for these devices with the ability to capture the information of said transactions and deliver it in the specific standard format known as CFX.

When exploring commercial EFM data acquisition solutions, it was observed that these systems did not have a driver to meet this requirement, a main reason for which the decision was made to develop this integration scheme as part of the SMADA solution. This component corresponds to a specialized service to acquire and automatically generate CFX files for EMERSON DL-8000 flow computers. Using the Modbus TCP protocol as a base and a set of algorithms and monitoring logics in the memory registers, it was possible to implement the EFM data capture mechanism for these computers. Once the CFX files were generated on the local server for each computer and each transaction, the available mechanisms, such as TorySync, were used to securely and reliably transfer the files to the servers in the cloud, where FLOWCAL processes them.

An essential point of this implementation consisted of this component’s ability to run in parallel with the Terminal Management System (TAS) without causing network interferences or interferences with the terminal’s daily operation.

Today, the EFM data acquisition solution implemented by Tory-Tech for these flow computers has been in operation for over a year. Significant benefits have been seen for the project and especially for the end-user, including:

1. Traceability and auditability of the entire data life cycle, from the information source, flow computers, to the product accounting areas.

2. Centralization and verification in the SMADA system of all the information on settlement transactions generated by the field’s flow computers.

3. Automation to capture all relevant data related to settlement ticket transactions.

4. Ability to safely and objectively evaluate the respective flow computers’ configurations, thus reducing the probability of errors in volumetric calculations.

Considering that EMERSON DL-8000 flow computers have a very important presence in several terminal installations and that until now, there was no standard mechanism for collecting EFM historical data, the development of this component within COSMOS®’s SMADA solution represented a very important advance for the implementation of these types of projects.

Diego Perdomo

Project & Automation Lead

Tory Technologies, Inc.

Recent Comments